makeSEA Analysis - Printing Conductive PLA from Proto Pasta with Replicator 2x - Resistance

Printing Conductive PLA from ProtoPasta with Replicator 2X - Resisitance

After suceeding with printing magnetic PLA, it wasn't a big problem to print conductive PLA. This material behaves very similar as normal PLA. With additional cooling and lubrication, it is possible to print PLA with 205°C nozzle and 60°C build platform on Capton. The material seems a bit more brittle compared with regular PLA, wich doesn't matter because it's conductivity is my primary interest.

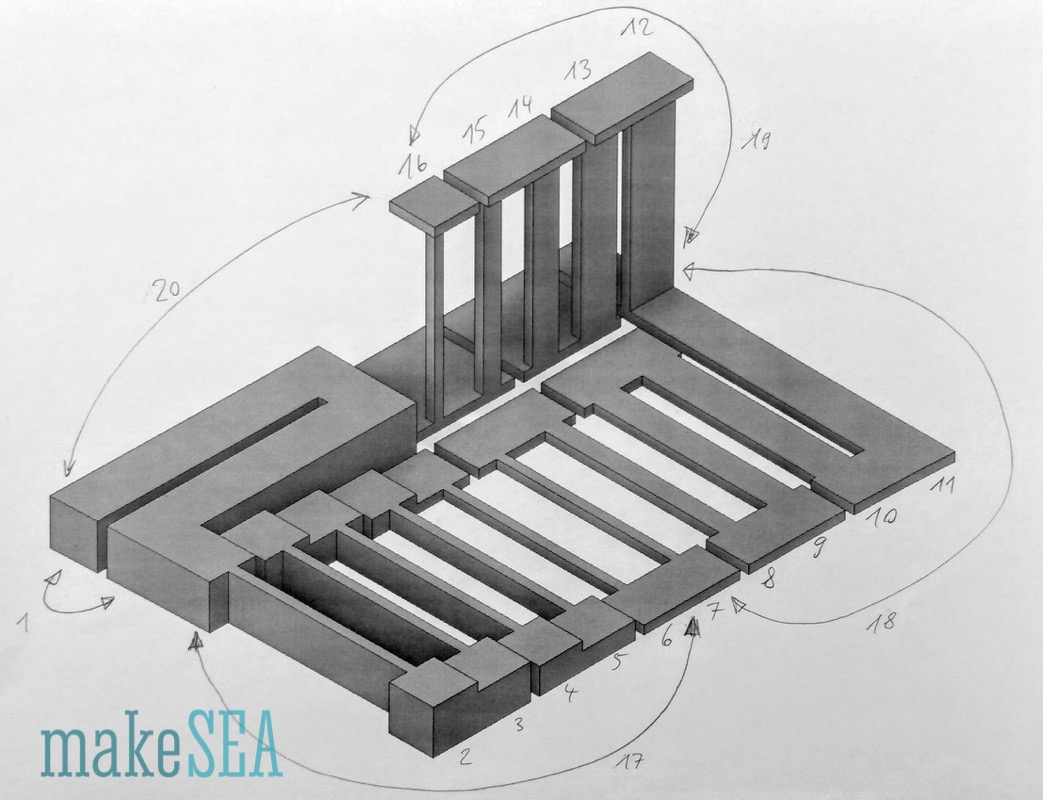

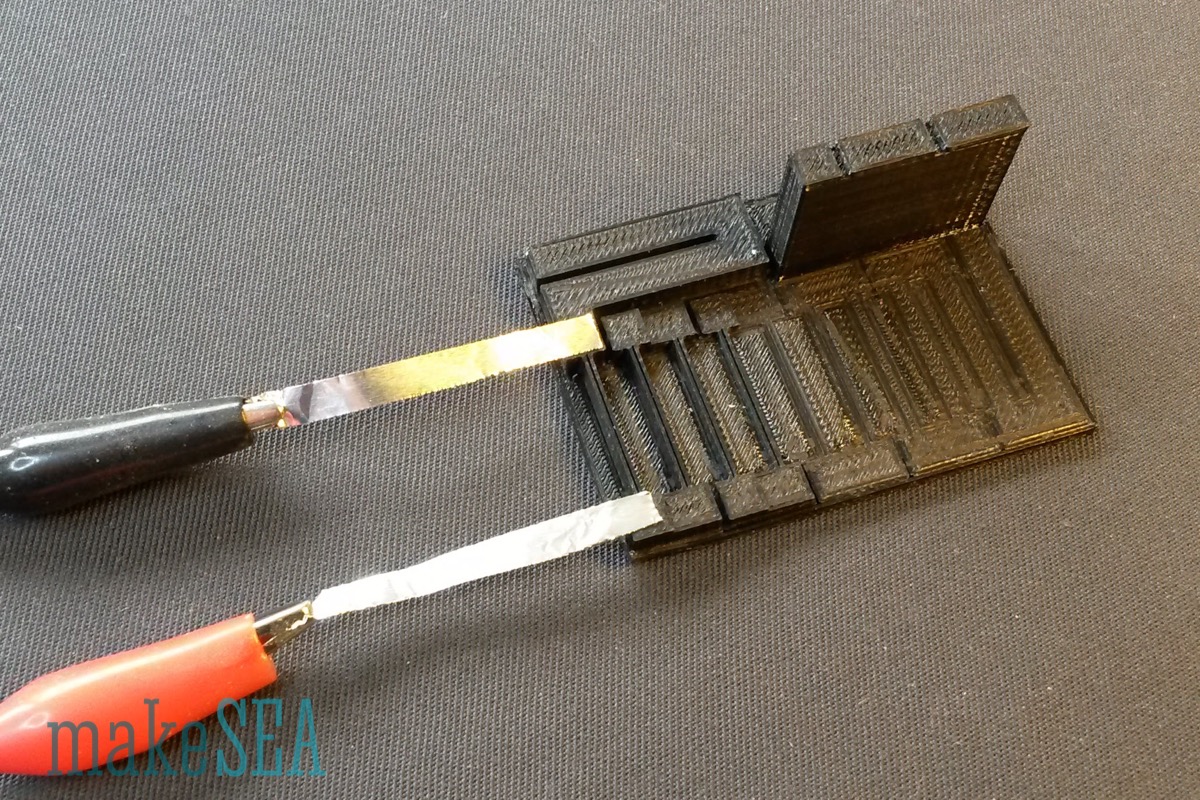

In order to measure conductivity (resp. resistivity), I created this design:

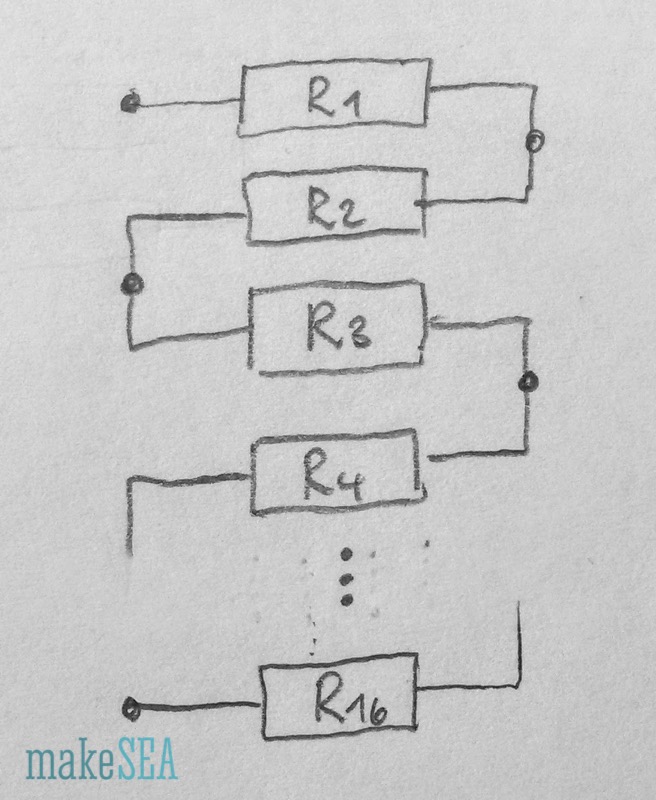

The design is a single connected wire with various shapes. Cross-sections are ranging from 1 mm^2 to 5 mm^2, the length of individual sections is 20 mm. In total 16 different resistors wired in series, with larger pads for contacting the measuring probes. The circuit scheme looks like this:

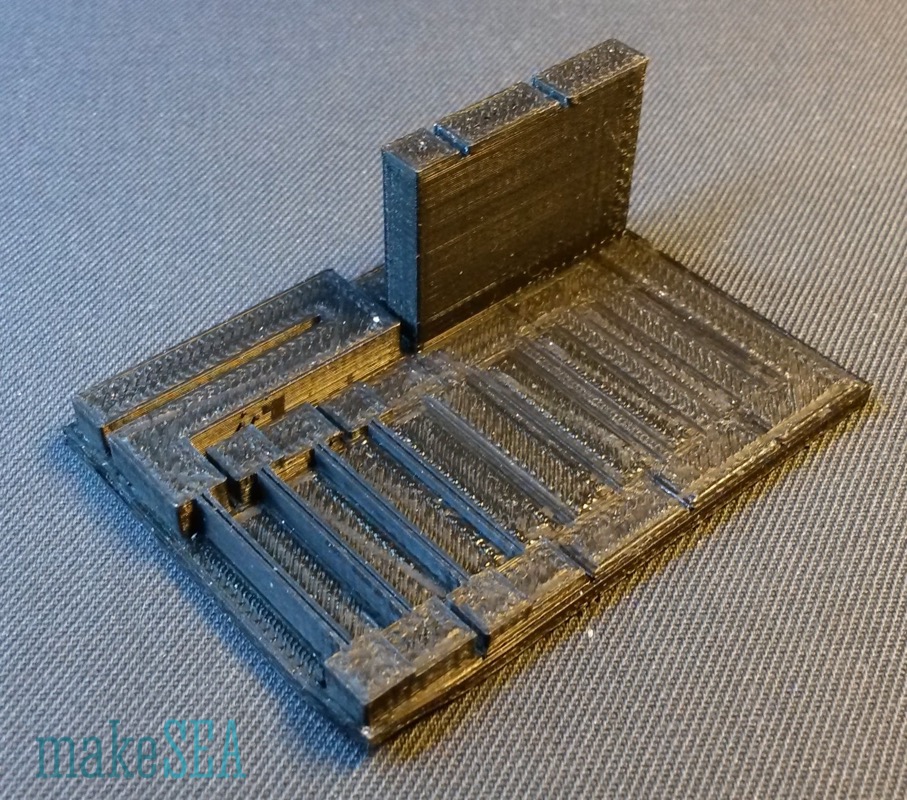

For 3d printing on the Replicator 2x I was using the original Makerbot Slicer Software and Simplify3D. In order to have maximum cunductivity I set infill to 95% (could also do 100%, but I was fearing a messy overextruded print, if parameters and filament are not perfect). As isolator I was using regular black PLA. The results from both slicers were similar.

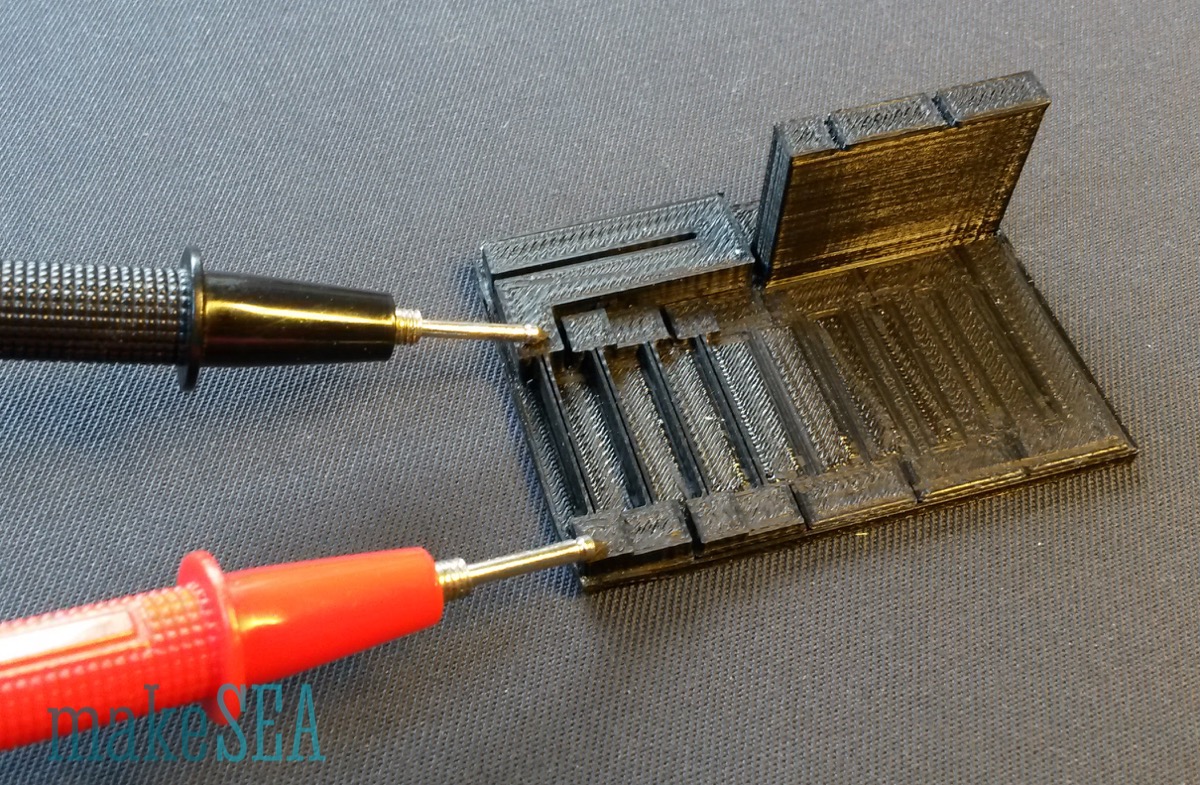

For measuring the resistance, I used two different methods.

|  |

The regular probes have only a small contact-area (almost only a point), and due to the relative high resistance of the PLA I expected to see a relevant difference compared with larger contact areas. For better contact I was using aluminium foil, which I pressed with my fingers to the PLA surface. I know, my body is also a resistor, and it could influence the results, but my own finger-resistance was in the range of Megaohms - not relevant, if result is kOhms ...

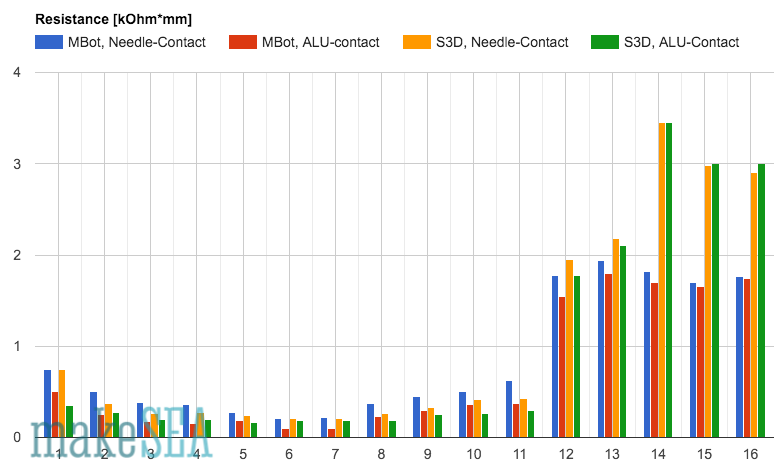

The chart shows the results from two printed models (one was sliced with original Makerbot software, the other was sliced with Simplify3D, both with similar parameters). And it shows measurements from 2 different contact types (explaned above). The measured values range from 1 kOhm to 10 kOhm for the horizontal oriented wires. Using cross-section area and conductor lenght, the specific resistivity could be calculated. Even dough my measurement methods were not very elaborate and accurate, it's clearly visible, that the printing orientation has a big influence: the resistivity horizontally along the slicing plane is much lower than the resistivity vertically across the slicing planes. Also visible the effect of contact area from the probes: for low Ohm wires the contact area can influence the resistance more than 50%, whereas for high Ohm conductors, it's less relevant.

The averaged values are in the range of the official Proto Pasta. The resistivity along z-axis probably depends also on the layer thickness (my prints have 0.1 mm layers).

| Resistivity Horizontal | 0.27 | kOhm*mm | official proto pasta: 30 Ohm*cm |

| Resistivity Vertical | 1.88 | kOhm*mm | official proto pasta: 115 Ohm*cm |

Conclusions:

1) Conductive PLA is useful for low-power applications (e.g. powering an efficient LED with a few mA)

2) Conductive PLA is difficult to use for "higher-power" applications (e.g. a microcontroller consuming more than 20 mA). Up to 20 mA the main problem isn't the resistance of the wire itself, because this can be designed with a large cross-section area. Problem is the contact area for a battery or the pin of the IC or any other current consuming device.

3) A bright flashlight with 1 W consumes roughly 300 mA. Assuming a minimal wire length of 20 mm. We don't want to loose more then 0.5 W over this wire. Let's calculate: R = P / I^2, and Area = Resistivity * Length / Resistance => Area needs to be more than 900 mm^2, if the wires have a square cross-section, the wire witdh needs to be 30 mm. In order to avoid additional losses the contact area from battery and LED has to cover the full cross-section. No useful application!

4) Avoid vertical oriented wires: having a closer look at the resistivities 14, 15, and 16 in the chart above, there is a significant difference between the prints sliced by Makerbot software and S3D. When inspecting the printed object, I realized that one of the higher layers from the S3D-print has a strange inconsistency (maybe underextrusion, or ambient temperature-change). Anyway in 3d-printing it's more likely that something goes wrong along the z-axis compared to the xy-axis, and the impact on the resistance can be huge.

3D-Model:

- SETP

- F3D

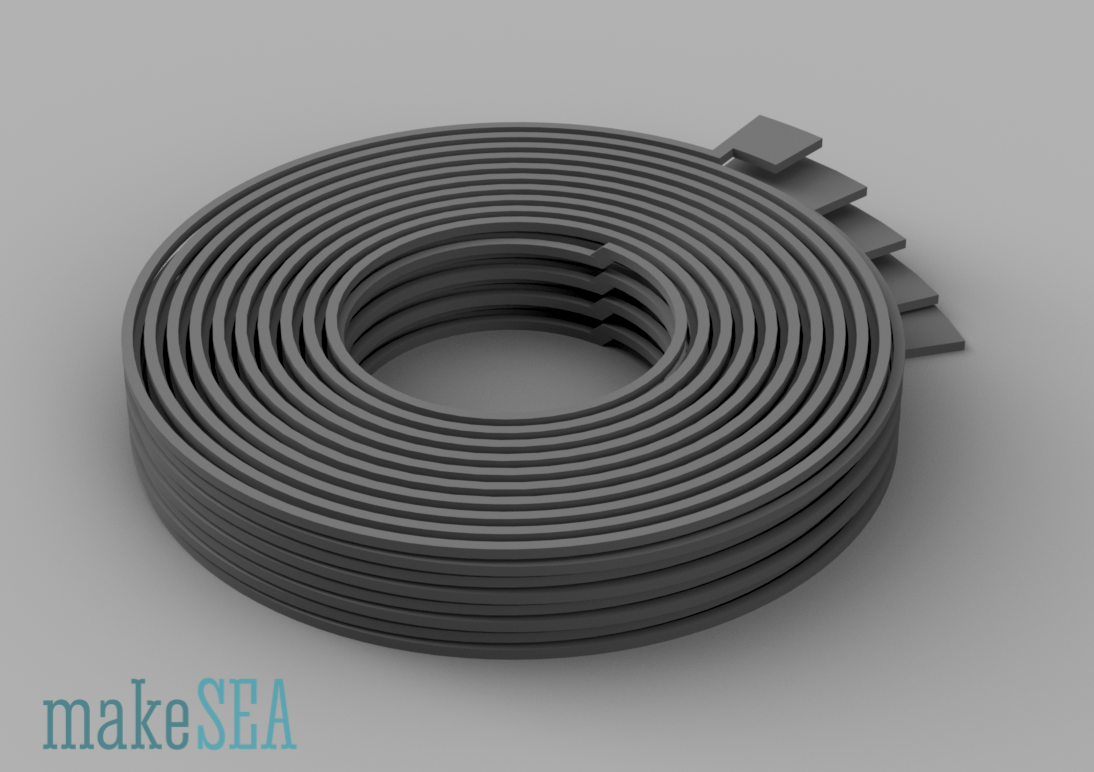

While I was wating for the conductive PLA beeing delivered, I already started creating some desigs for testing. I was also interested to see, how the material can be used for printing a coil:

I've not yet printed it, because I expect inferior usability due to the high resistance. Here are some numbers:

| Outer Diameter | 50 | mm |

| Inner Diameter | 20 | mm |

| Height | 10 | mm |

| Cross-Section | 0.49 | mm^2 |

| Resistivity | 0.3 | kOhm * mm |

| Wire Length | 8'000 | mm |

| Turns | 80 | |

| Resistance | 4'898 | kOhm |

| Current | 0.001 | mA |

| Voltage | 5 | V |

| Inductance | 180 | uH |

(using http://coil32.net/online-calculators/multilayer-coil-calculator.html for inductance calculation)

In order to create a small magnetic field, there needs to be a certain amount of current. However the resistance is incredible high (5 Mega Ohm), and with 5 Volts there is only 1 Microampere Current. This design is not usefult as a magnetic actor! Probably there is no design, where the conductive PLA from Proto Pasta can be used as actor (motor). The resistivity would need to be MUCH smaller!

Maybe there is an application as sensor? Maybe I should give it a try to print this design at some time.

Conductive PLA sourced from:

Pictures and video don't convert like first-hand experience does.

Research shows that using augmented (AR), and virtual reality (VR), is more compelling and more likely to persuade your audience to buy, learn, and understand what you have to share. Use makeSEA to deliver content that connects with your audience like no other medium can.

Compel your audience with

Content Management and Cross-Platform Collaboration

for Augmented and Virtual Reality

The fastest way to organize and share your content as if you are together with your audience in real life and keep it fresh using next-generation virtual and augmented reality technology.

It's time to change the way you communicate, collaborate and compel your audience.

Time to change the way you capture and curate evolving ideas.

Use makeSEA content management platform + Catapult, our cross-platform client app for mixed reality and spatial collaboration to share your vision and inspire your audience with content that you are already producing.

10X-100X Time Savings • Recyclable Content & Scenes

Use makeSEA to reduce your AR and VR production time by an order of magnitude, or two.

Blend content from multiple sources tell a better story: 3D models, real-world scans, video, and you!

Keep things fresh and relevant and improve experiences over time as your content and XR technology mature.

Enabling augmented reality, mixed reality and spatial computing for everyday use.SM

Catapult your vision, in real-time together, for FREE.

It's as easy as a social media post:

-

Create an account, start a project and upload your content from most any content source1.

-

Launch Catapult, makeSEA's mixed reality client app on your VR or AR compatible device2.

-

Share and collaborate using your own spatial content, with others together in real-time, in the same physical space and remotely.

Click Here to Get Detailed Instructions, Download and Install

Try makeSEA now! Simply register here and start publishing.

makeSEA is also available as a privately branded (white-label), or custom integrated solution for enterprise. Please Contact Us for more information.

& Design

AR/Mixed Reality

Content Publishing

& Making

& Exhibits

& Branding

1:Catapult supports assets saved in GLB (preferred), FBX, OBJ, STL or MP4 (standard 720p, 1080p, or 3K 360˚ spherical surround format), or a makeScene package for live over-the-air collaboration with shared spatial content. See the how-to guide for hints and instructions on how to easily export or convert content from most 3D authoring tools and platforms. 2:makeSEA supports Oculus Quest 2, Magic Leap 1, and Microsoft Hololens 2, makeSEA for Enterprise supports additional client devices; contact us for more information.

Trade Show Alternative

Trade Show Alternative