Details

Details  Print

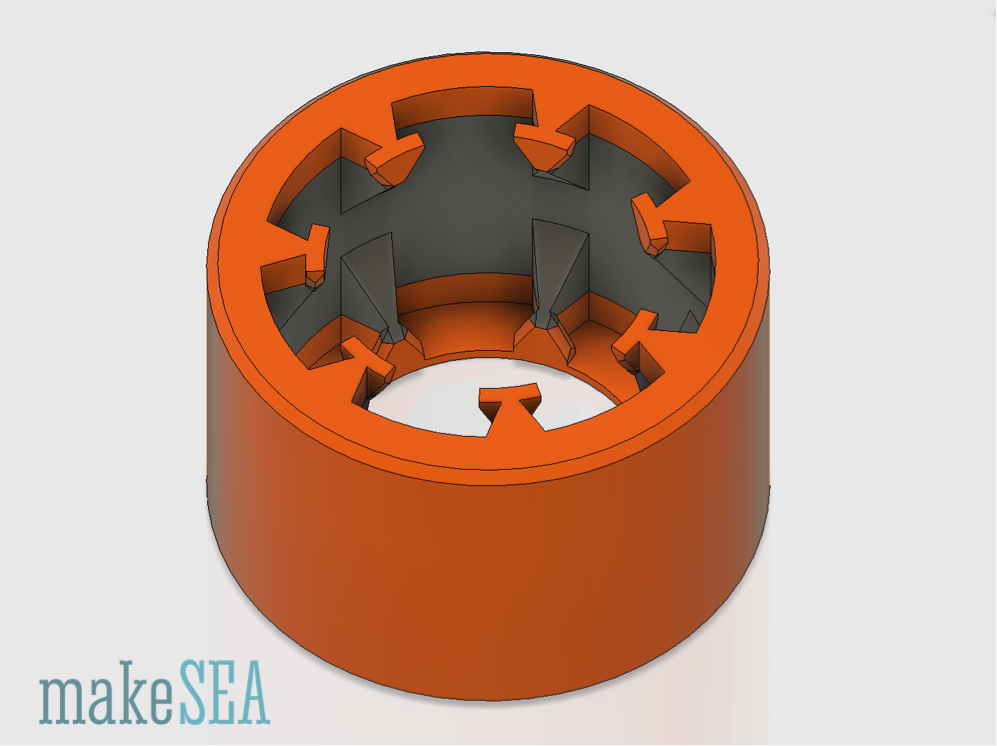

Print I thought I knew, how it works to print magnetic PLA from Proto Pasta, so I started to design more complex objects. Actually I wanted to know, how magnetic PLA works in combination with regular PLA on the R2x. So I’ve designed a cylindrical object, which has regular PLA as an outer shell (orange), and magnetic PLA inside (gray). This part could potentially be used as a rotor for a brushless motor.

It was quite a challenge to find good slicer settings for getting this printed - I tried it with Makerbot Desktop and Simplify3D, and after several experiments I was still not satisfied.

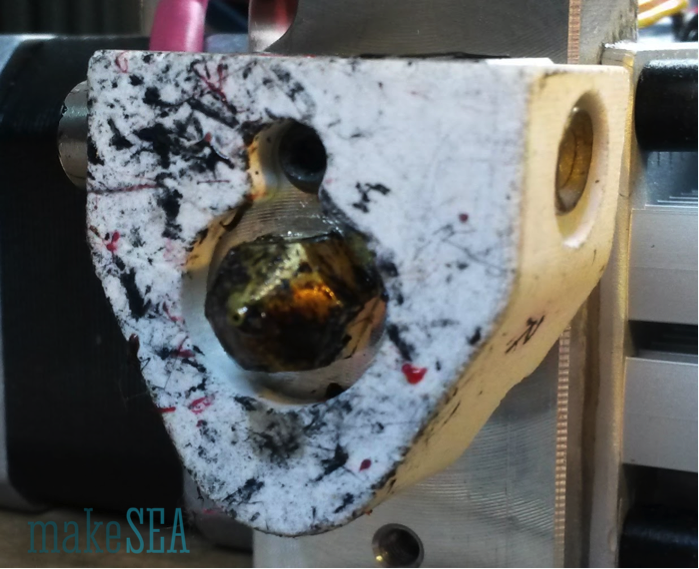

While the result got better with each printing iteration, all of a sudden the magnetic PLA stopped printing. The nozzle clogged. I was guessing the same happened as I initially experienced: a cold end clog. So I expected, that this is simple to resolve - just heat up the nozzle, unload and reload the filament, and it should work. Wrongly expected, no magnetic PLA was extruded. Also additional manual force or even higher temperature didn’t help. So it was clogged differently, and I had to fully disassemble the extruder. Big frustration - the initial experiment wasn’t finished, and the amount of effort to reach the goal increased a lot. But there was no alternative, so I started my analysis at the feeder, and it ended at the tip of the nozzle.

After removing the nozzle from the heater block, it was obvious to see, that there was no passage through the nozzle. I heated up the nozzle carefully with a soldering iron (temperature controlled) and was pushing a thin copper wire into the nozzle, hoping to push the blocking material back out of the nozzle. It failed. It seemed that the thin extruder hole was clean, and the clog was further up and extremely compact.

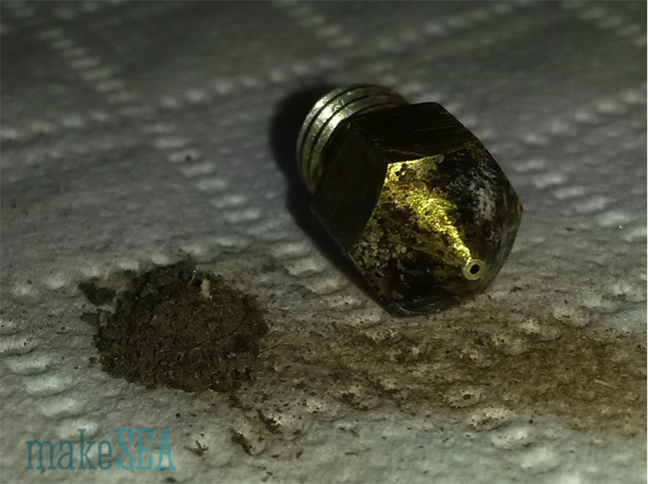

Finally I took a larger drill-bit, pushed and turned it by hand into the nozzle (from the end of the threads). Grinding the clogged material. The material, which tickled out of the nozzle had a funny consistency: I had expected, it should be a bit like plastic, but in fact it was mostly powder. When heating the powder up (solder iron), it didn’t melt, and remained a powdery substance. And it was very magnetic too. At a guess the clogged part had been 5 mm thick, almost 100% very compact metal powder, and no PLA. I also cleaned the outside, which has no functional effect, it just looks better. After re-assembling (and re-calibrating) the R2x, it worked again. The question remains: what had happened?

I don’t have a final answer for this - my explanation is mainly a guess:

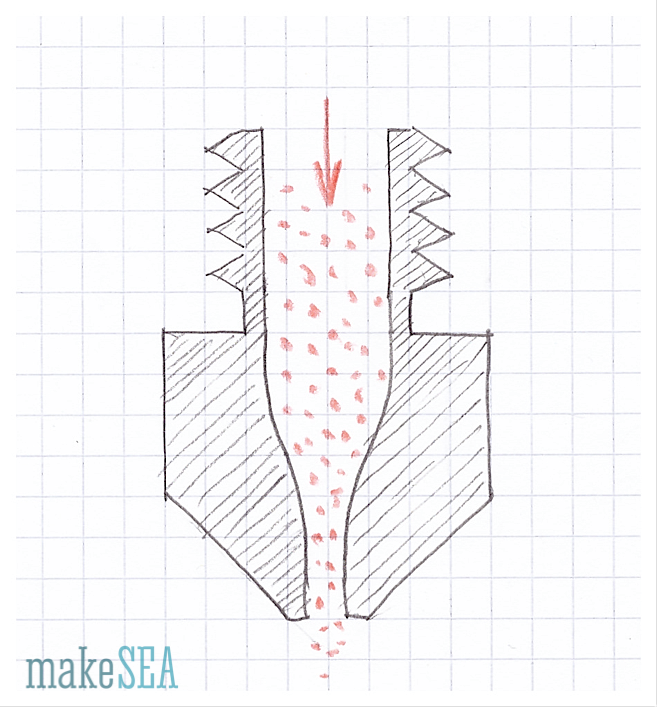

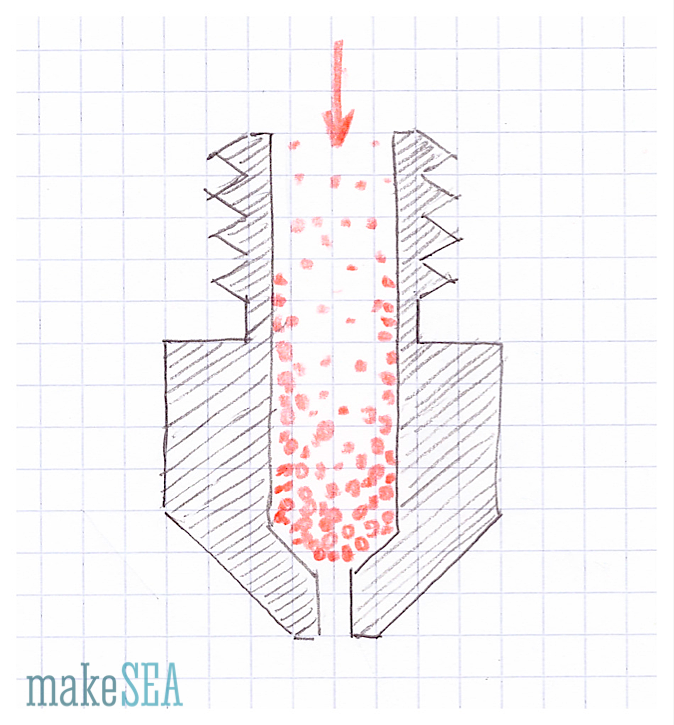

Magnetic PLA is a mix of iron powder and PLA. The powder particles build a sediment at the inner walls of the nozzle. Especially in the corners, where the tip of the nozzle gets thinner. While the sedimentations initially don’t disturb the flow of the material, the funnel gets smaller and smaller over time. Finally the nozzle is fully closed by iron powder sedimentation.

Potentially there is another negative effect: with dual material prints, there is a long idle-time, where a heated nozzle travels and oozes around. Because of the reduced flow of material, there are less iron particles flushed out of the nozzle. The process of sedimentation / dehydration is accelerated, PLA with less iron powder is dropping out of the nozzle.

Maybe the used oil for filament lubrication has also a negative effect? What happens actually with the oil in the nozzle? Does it mix with the PLA or is there even a chemical reaction? Or does it burn? The oil I used is specified to work up to 200°C and the removed clogged powder appeared to be only magnetic and not oily or carbonized at all.

I further decreased the extrusion temperature - assuming that the sedimentation process is reduced, if the carrier material is less liquid. Reducing the oozing would anyway be good to get better printing results. Finally I was setting 200°C for the magnetic PLA, and 195°C for the regular PLA (which was also oozing a lot at 205°C). It probably won’t avoid that the clogging happens again, but I hope it takes longer, until the next clog.

Probably not only magnetic PLA has the risk to get stuck in the extruder nozzle. All 3d-printable materials are affected, which are a mix of powder and plastic with different density, and different behavior of adhesion or flow. E.g. materials containing carbon, glass or wood. Finally the nozzle should have an optimized interior shape ideally with a smooth (maybe even coated) inner surface. Giving the the particles no chance to settle or stick. Does such a nozzle exist, compatible with R2x?