Details

Details  Print

Print

Design a parametric propeller, useful as a fan or for an RC-plane.

Basically I wanted to know, if it is possible at all to create a 3d-printable propeller, which works with a satisfying efficiency. When successful it would be very useful, because pitch and diameter were freely adjustable, and I’m not restricted to the off-the-shelf propellers. The geometry of the propeller and the hub can be optimized for a specific the plane.

The basic version of the propeller has 9 inch diameter and 4 inch pitch. The design allows to change both parameters, and also the number of blades from two to three (1 blade doesn’t make sense, and with 4 or more blades, the hub diameter needs to be increased as well in order to have enough space for the blade shafts).

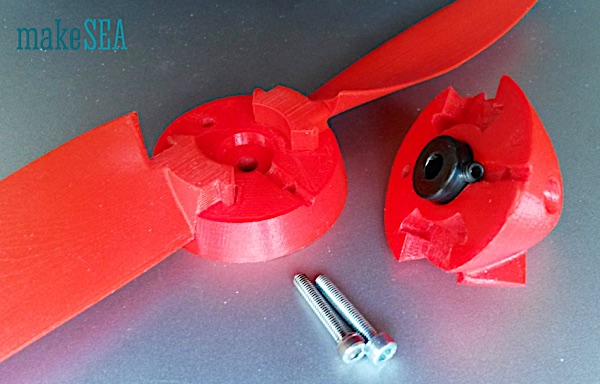

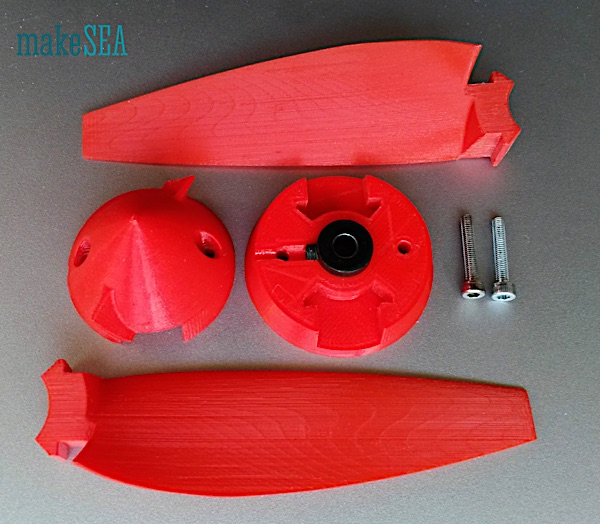

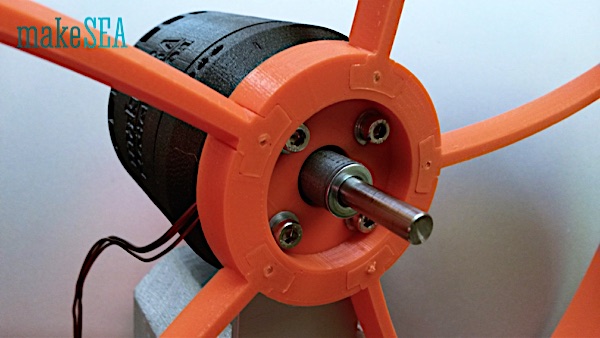

Blades and hub are separated parts. The two or three blades fit tightly into the gaps of the two pieces from the hub. The hub encloses a shaft collar. The set screw of the collar is used as cam. The two parts for the hub are held together with two or three screws (depending on the number of blades).

There are various benefits of having separated parts:

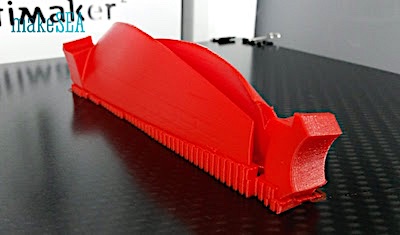

The image below illustrates the recommended printing orientation. As visible, it requires support material. The supported area at the front of the propeller is small and easy to sand. Anyway it is a good idea to also sand the surface of the blades. 400 grit with water gives good results.

As material I recommend using PETG (and not PLA). I fear the brittle PLA can break catastrophically at higher RPM, if there is a little shock. I didn’t do a test to figure out the limiting RPM, but the PETG-version did work well on a plane with a common brushless motor at 10’000 RPM.

I’ve replaced a common 2 bladed propeller with the 3d-printed version. Both propellers had the same diameter and pitch. The plane has a weight of roughly 350 g and 700 g thrust (twice the own weight). Performance was almost unchanged - there was no noticeable difference during flight. On the ground, the 3d-bladed propeller draws a bit more current, but the flight duration was still similar.

If the Propeller is used as a fan, I recommend to print also a guard. The most dangerous parts are the fast moving tips of the blades, because they can easily cut through human skin. For this reason the guard consists of a ring around the propeller. This ring has a proper airfoil as a cross-section, so it works as a duct (and maybe even improves the propeller efficiency).

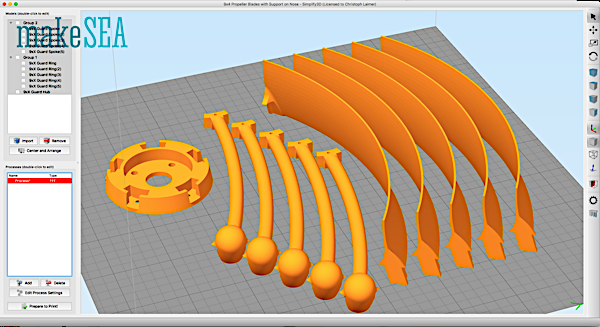

The ring is too large for a common 3d-printed, so I divided it into 5 separate parts.

The next image shows how to orient the objects for 3d-printing.

Support material needs to be activated in order to print the overhanging structures.

The ring is held together by rails at the end of the spokes. Because of the angled orientation, the ring segments won’t slide out, when fully assembled. Fife small screws are needed to fix the spokes at the hub.

The holes in the hub are compatible with the 3d-printed brushless motor.

Additional Information: