Details

Details  Print

Print

Magnetic PLA from Proto Pasta must be useful as core of an electromagnet. Without knowing its physical properties, I just built a brushless motor using this material, and it worked! But there is still the question: How much does it really help?

In order to find the final answer, I should assemble two identical motors, where only the material of the core is different. But winding an entire stator is a lot of work, so I’ve done more basic tests first.

Simple Coil

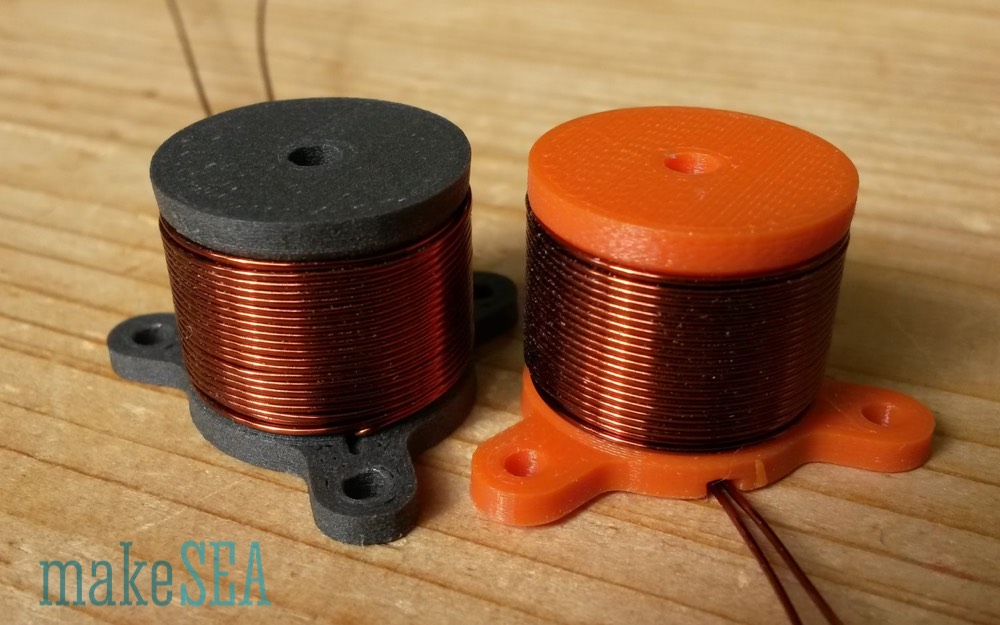

I’ve designed a core for a simple coil, and 3d-printed it with PETG and magnetic PLA from Proto Pasta. These are the common properties:

| Coil Length | 11 | mm | |

| Coil Diameter inside | 16 | mm | |

| Coil Diameter outside | 18 | mm | |

| Turns | 40 | (2 layers, 20 turns each) | |

| Wire Diameter | 0.44 | mm | (0.5 mm with isolation) |

| Wire Area | 0.15 | mm^2 | |

| Wire Length | 2,296 | mm | (incl. 80mm long connection wire) |

| Resistivity Copper | 0.017 | Ohm*mm^2/m | |

| Resistance (measured) | 0.27 | Ohm | |

| Resistance (calculated) | 0.26 | Ohm |

If the coils are used as inductor in an electrical circuit, it has the following measured values.

| PETG | Magnetic PLA | ||

| Inductivity | 24.4 | 31.3 | uH |

The inductivity of the coil with the magnetic PLA is 28% higher.

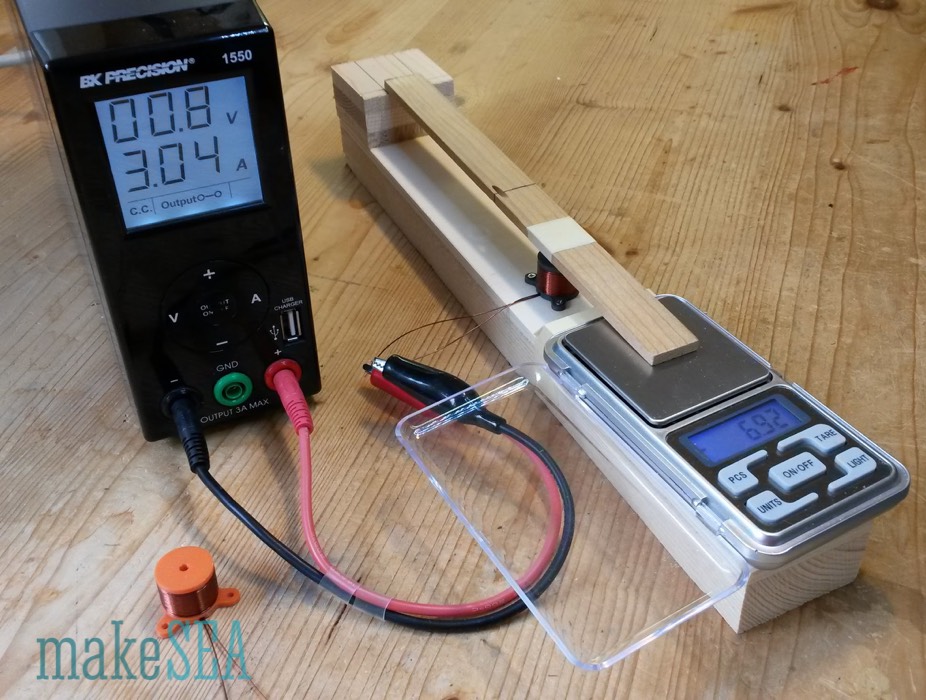

That’s not telling a lot about the brushless motor. For the motor the torque, resp. The magnetic forces are interesting. So I’ve created a setup, using a scale, a wooden bar (lever), and a constant current power supply.

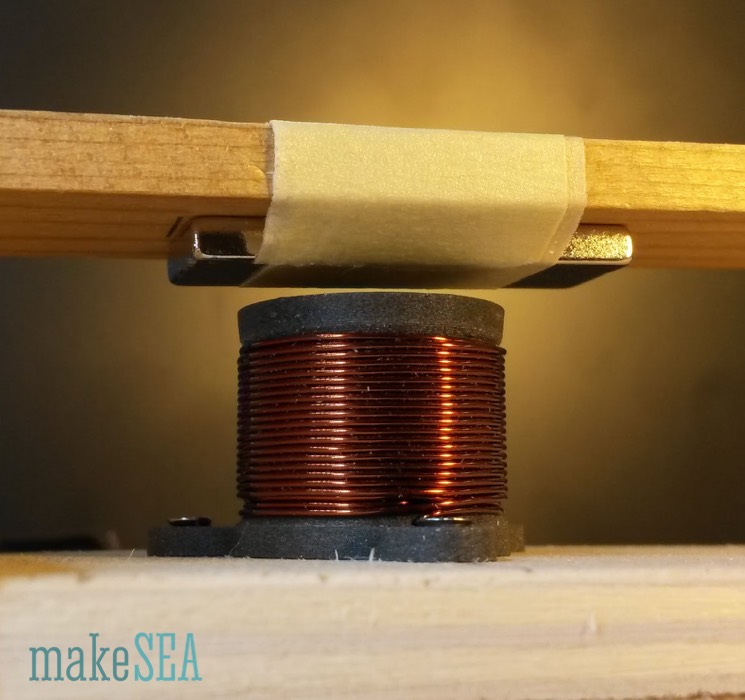

A permanent magnet (30x10x3 mm) is fixed on the lever above the coil (electromagnet). The electromagnet is firmly fixed on the ground (large bar). If the electromagnet is powered, the permanent magnet is attracted (or repelled). ⅓ of the force is applied directly on the ground, ⅔ are applied to the scale (approximately - the law of the lever). The setup allows to replace the electromagnet, and hence compare them. The absolute values of the forces are not interesting, because finally only the ratio between the different materials is interesting.

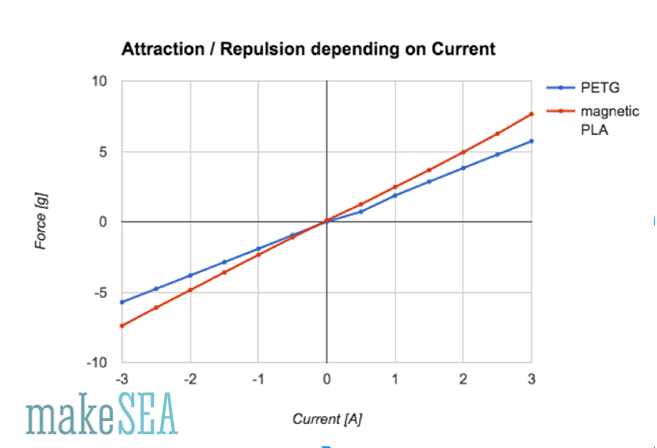

In a first experiment the distance of the magnet was kept constant (at roughly 1.5 mm), and the current was changed from -3A to +3A.

The measured values are on a straight line. This is not really surprising as it is basic physics: https://en.wikipedia.org/wiki/Lorentz_force#Force_on_a_current-carrying_wire

More interesting the differences: The force created by an electromagnet with magnetic PLA as a core is 34% higher compared to an electromagnet without ferromagnetic core (air).

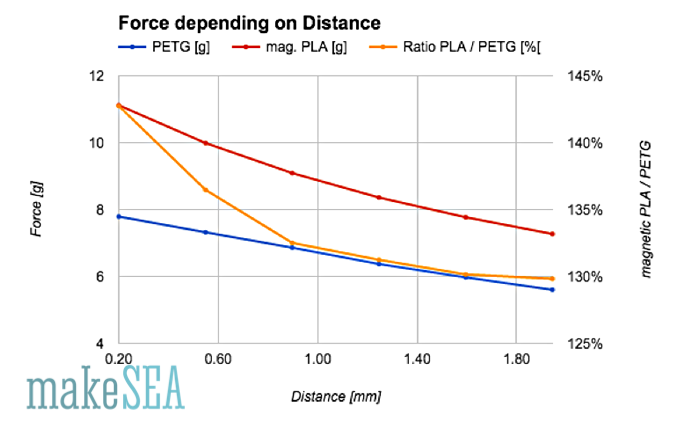

For the next experiment I’ve kept the current constant at 3A, and changed the distance of the magnet by adding sheets of cardboard between lever and scale.

The ratio of magnetic PLA and PETG changes depending on the distance. The the increase of forces ranges from 30% to 43% for the measured distances. Probably the minimum increase goes to 0% for larger distances.

The range is quite large - I didn’t expect such a variation. Probably the “cap” of the spool as an influence to these measurements. The PLA-spool has the advantage, that the “magnetic distance” between the copper wire and the permanent magnet is shorter. This kind of comparison would be more “fair” if there was no cap (core ends right at the last turn of the coil). Anyway, this simple setup demonstrates, that the reality isn’t really simple to pack into formulas.

Generator / Kv

What is the effect of magnetic PLA from Proto Pasta, when it’s used as stator of a Generator (resp. brushless motor)? How big is the induced voltage?

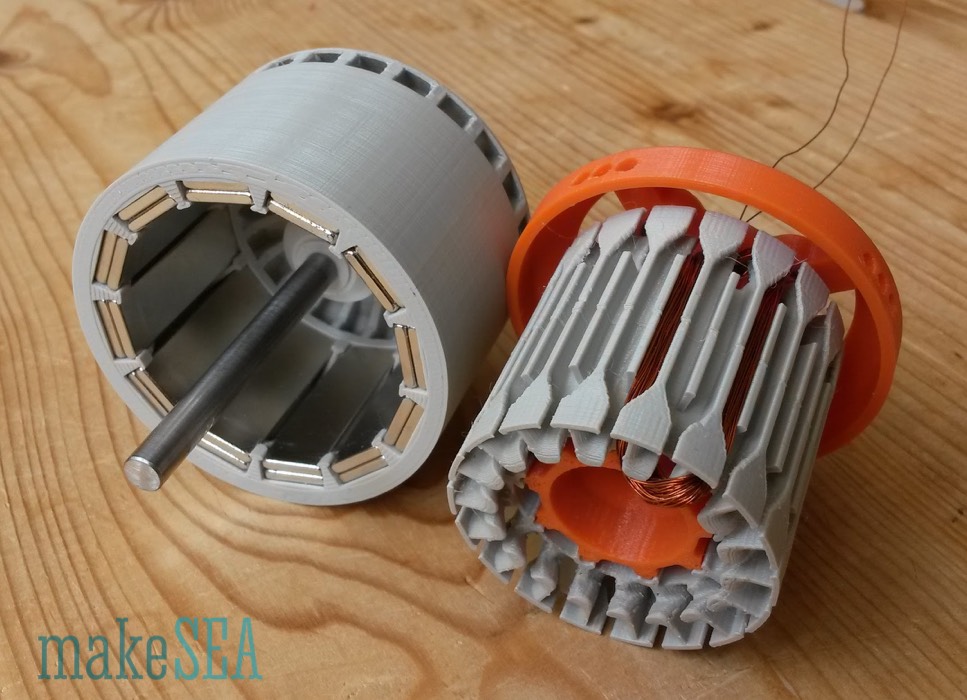

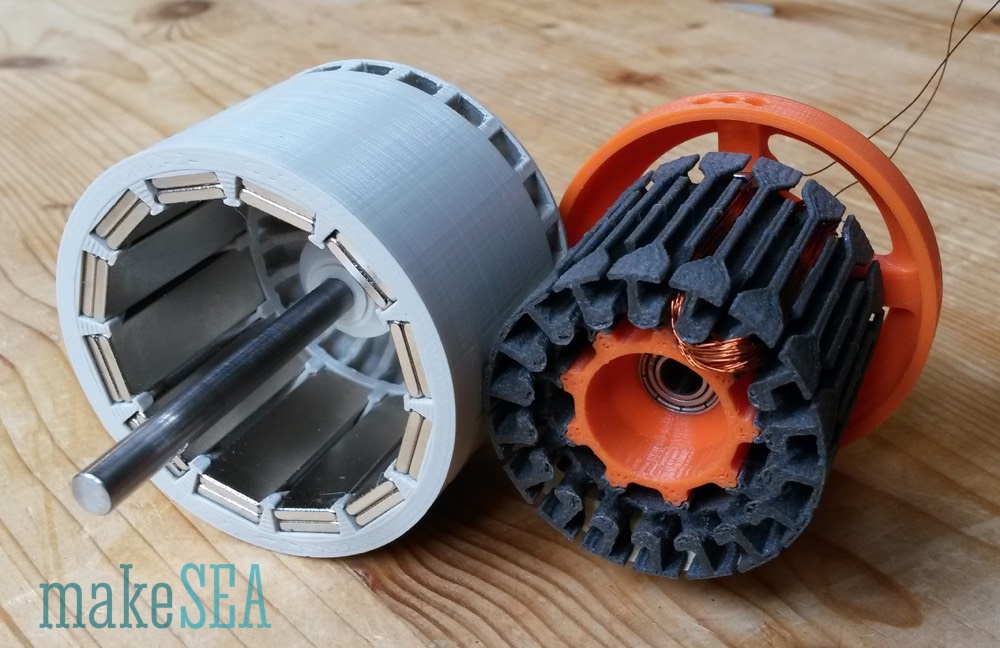

The question did arise, when I started the design of a generator, which should produce a relative high voltage already at low RPM. For this reason an efficient stator is needed for the copper wires, and it needs to have many turns per tooth. In order to find an answer, I’ve printed the same stator from the brushless motor model A001.1 with PETG and magnetic PLA. Because I wanted to have a quick answer, not all coils were wound, but only one coil of one phase.

In the images above a rotor with 2x2mm magnets was use. Magnets are a bit stronger than the 3 mm magnets from earlier experiments. For the current experiment it doesn’t make a difference, because the same rotor was used for both types of stator. For both stators the same copper wire and number of turns was used.

| Unit | ||

| Wire Diameter | 0.21 | mm |

| Turns per Coil | 63 | |

| Wire Length per Coil | 6’150 | mm |

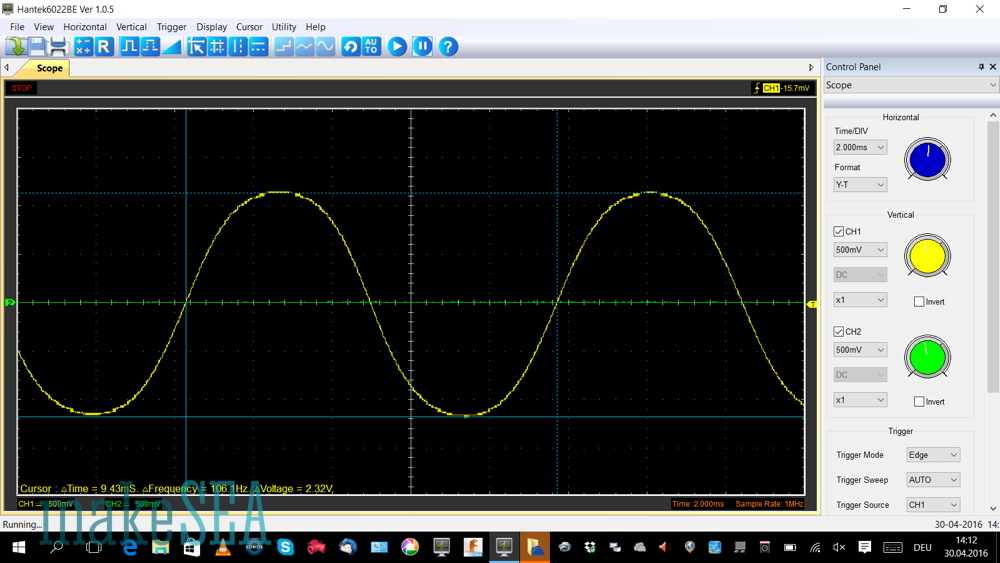

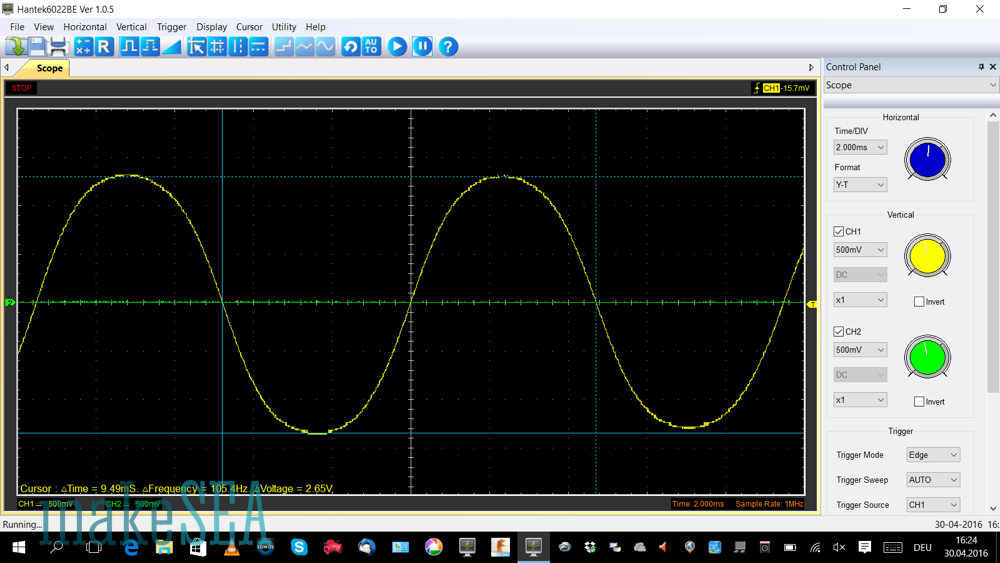

These are the measurements with the manual drilling machine and the scope on my laptop. On the left the PETG core, on the right the magnetic PLA core:

As expected, the generated voltage with the magnetic PLA core is higher. The frequency is also a bit different, so let’s compare the proper Kv of the two configurations. A fully wound stator had 6 coils per phase, and 3 phases. Phases are connected in star configuration.

| PETG | magnetic PLA | ||

| Amplitude single Coil (measured) | 1.16 | 1.325 | V |

| Rotation Speed (measured) | 1’061 | 1’054 | RPM |

| Kv (calculated) | 92.64 | 80.5 | RPM / V |

Compared with a non-magnetic material (in our case PETG), magnetic PLA used as a stator core the generated voltage is 15% higher.

Conclusion

The expected Kv of this generator is very low. That’s great for producing relative high voltage at low RPM (with only 600 RPM it generates over 7V). However the benefit of magnetic PLA is not dramatical. 15% is not nothing - especially if I’m interpreting as 15% saved manual winding effort.

Other test-setup have demonstrated that magnetic PLA can increase forces up to 40%. The design has a relevant influence on the actual performance.

If the design isn’t completely bad, the win of magnetic PLA is certainly larger than 10%, but it’s not higher than 50%. It’s unrealistic, if one would believe, magnetic PLA could increase the performance by a factor of 2. Electromagnetism and permeability isn’t trivial. I guess the ratio changes, if there is a heavy load connected to the generator, or if it was used as a motor.