makeSEA Knowledge - Printing Magnetic PLA from Proto Pasta with Replicator 2X

Printing Magnetic PLA from Proto Pasta with Replicator 2X

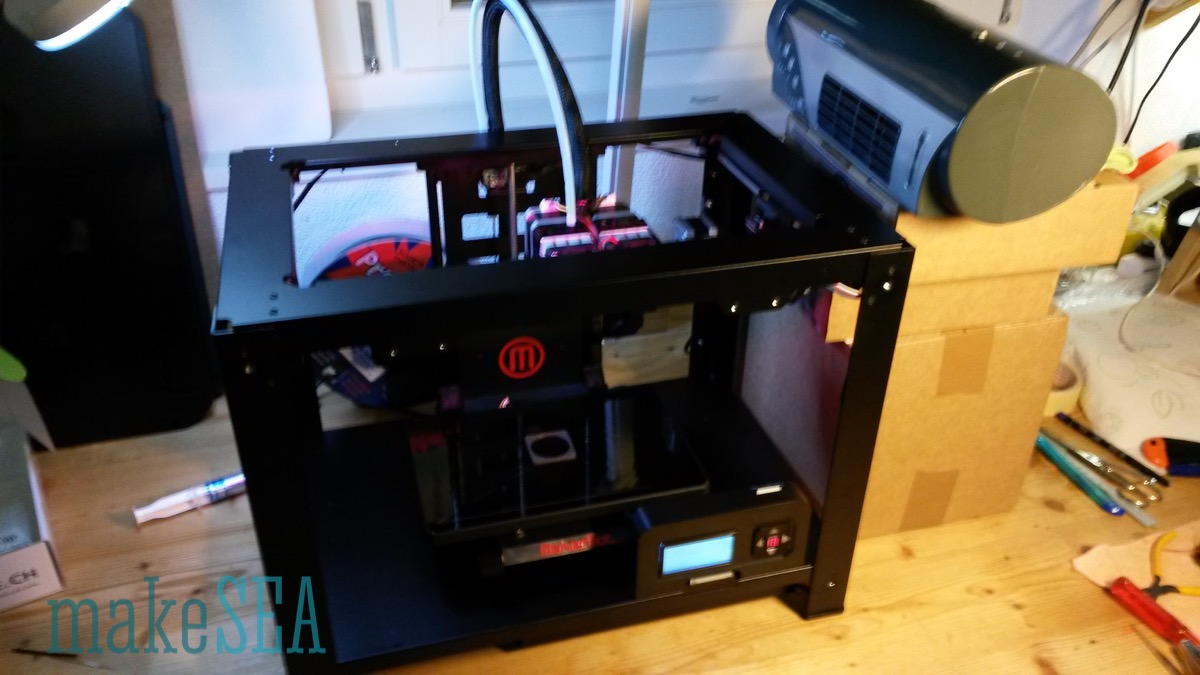

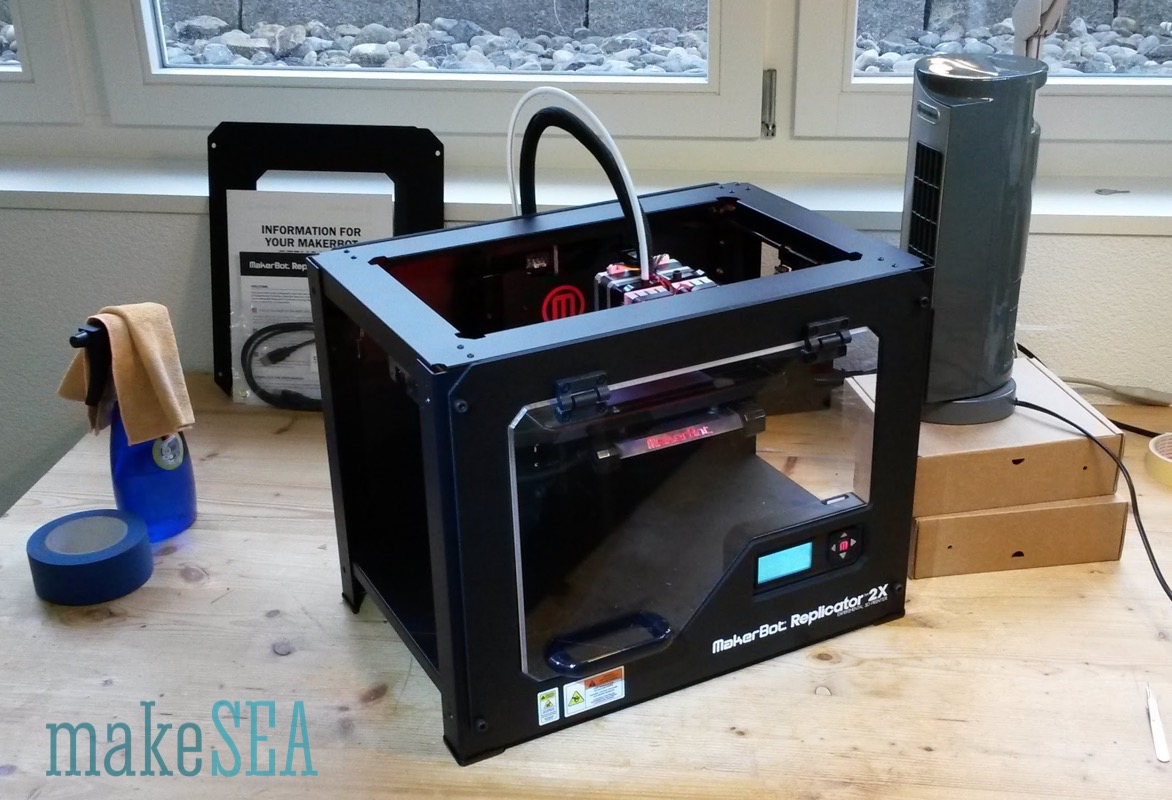

There are nice new 3D-printable materials. How cool would it be to design objects which contain materials with different properties, different than just colors. So I ordered a Replicator 2+ and some spools of filament from Proto Pasta. When it was finally delivered, I couldn't wait to try the magnetic PLA (actually it should say âÃÂÃÂferromagneticâÃÂàbecause the material is not a permanent magnet, but it can be attracted by a magnetic field).

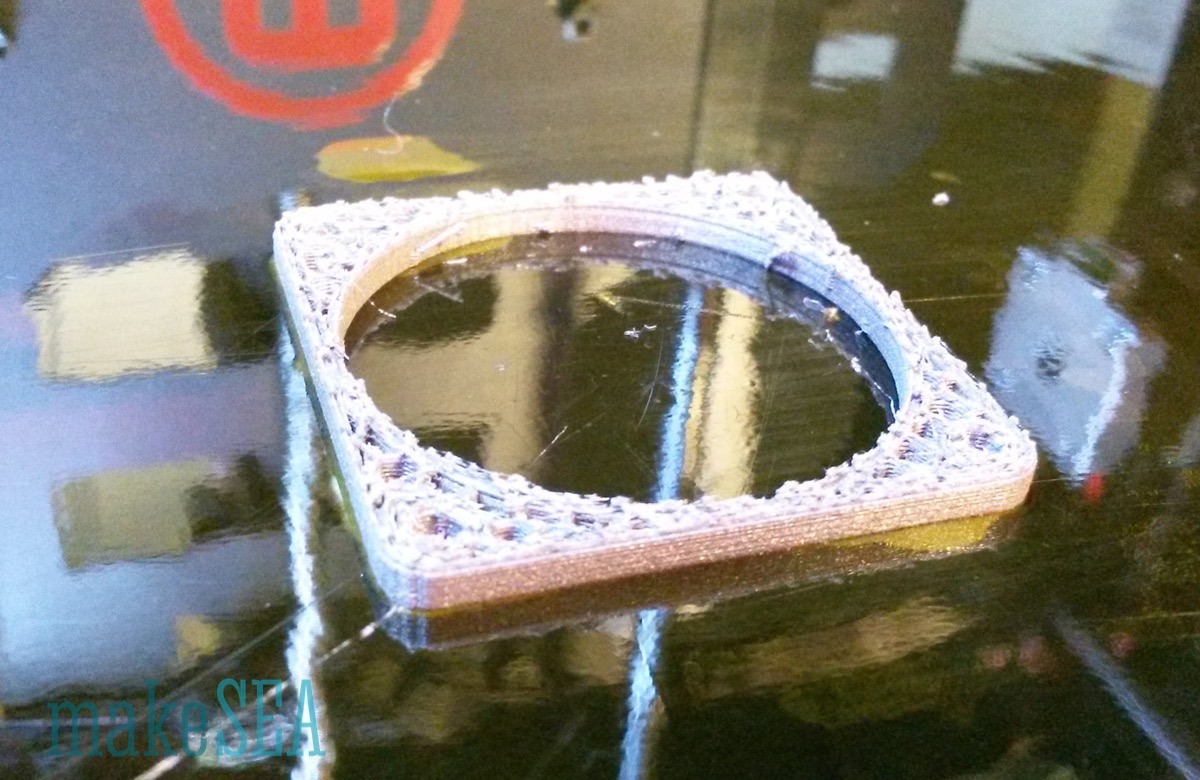

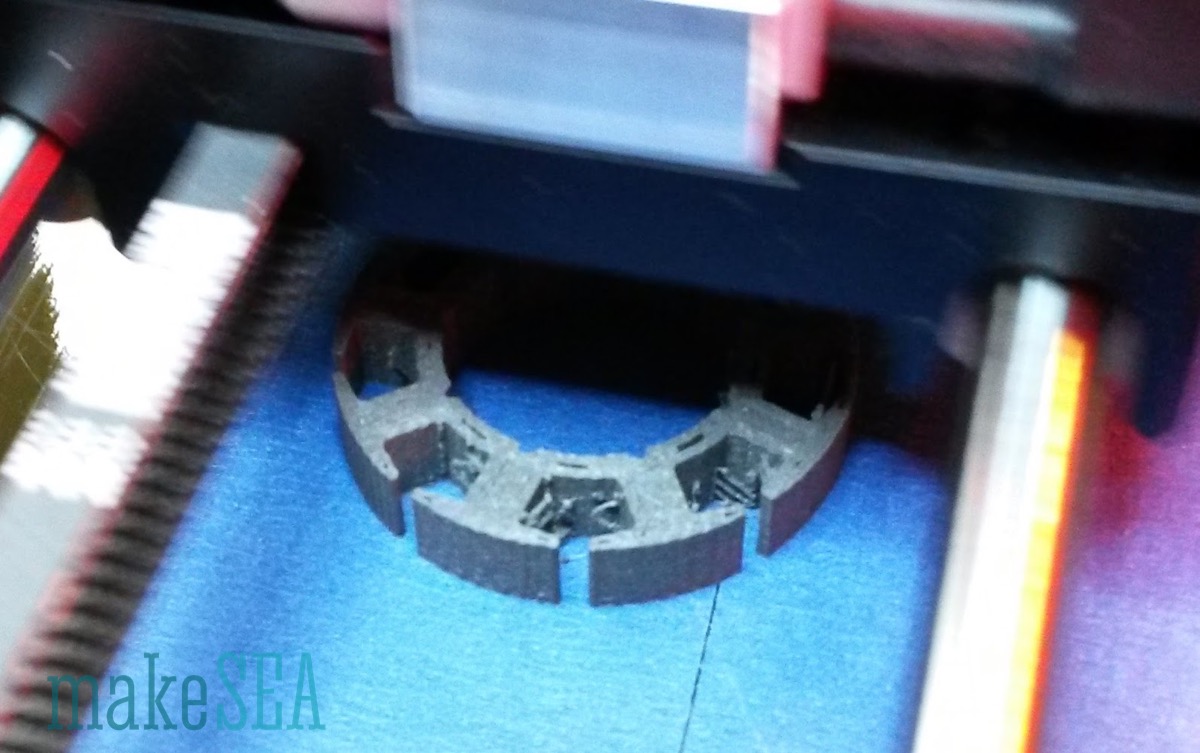

This is the result, when I was using the Makerbot Slicer with default PLA values (230ÃÂðC) and the magnetic PLA from Proto Pasta:

The printing worked well on the first layers, but all of a sudden it stopped. The feeder motor was skipping steps.

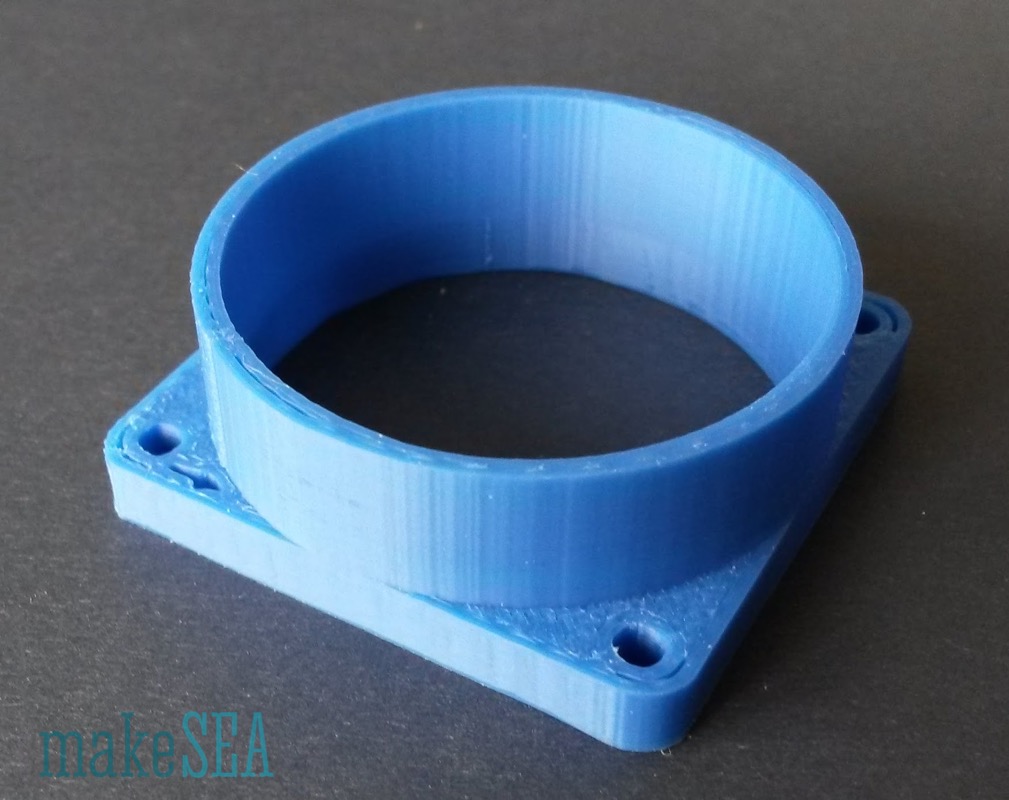

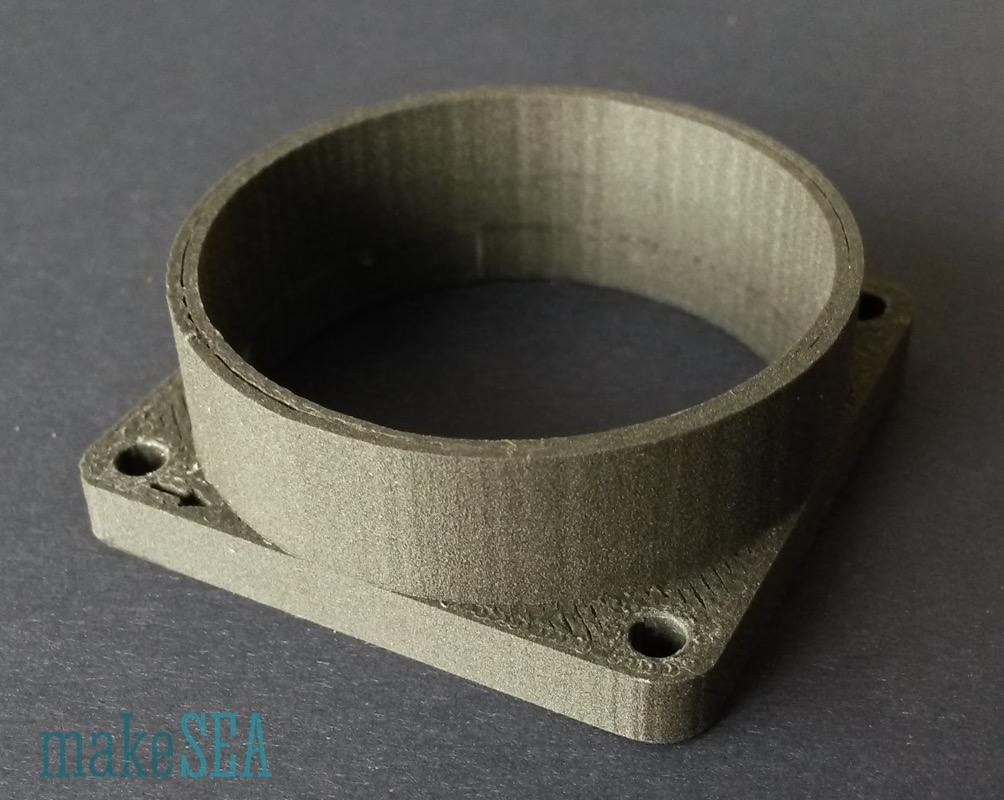

The test-object has a shape of a short cylindrical tube with some sort of flange and screw-holes. Diameter is 40 mm and height is 15 mm.

STL: /documents/12185/33773/TestCylinderWithFlange.stl/f794b6cb-1379-4924-91fa-72372dc7183a

STEP: /documents/12185/33773/TestCylinderWithFlange.step/b0b08d23-2dcf-4e15-9d05-5426d5e227d9

F3D: /documents/12185/33773/TestCylinderWithFlange.f3d/5b1a17ad-b568-44f0-b146-9f0768920335

With blue ABS the printing had succeeded:

I played with different temperatures from 190ÃÂð to 230ÃÂð, but it still stopped after a few layers with the feeder sometimes grinding, sometimes skipping steps.

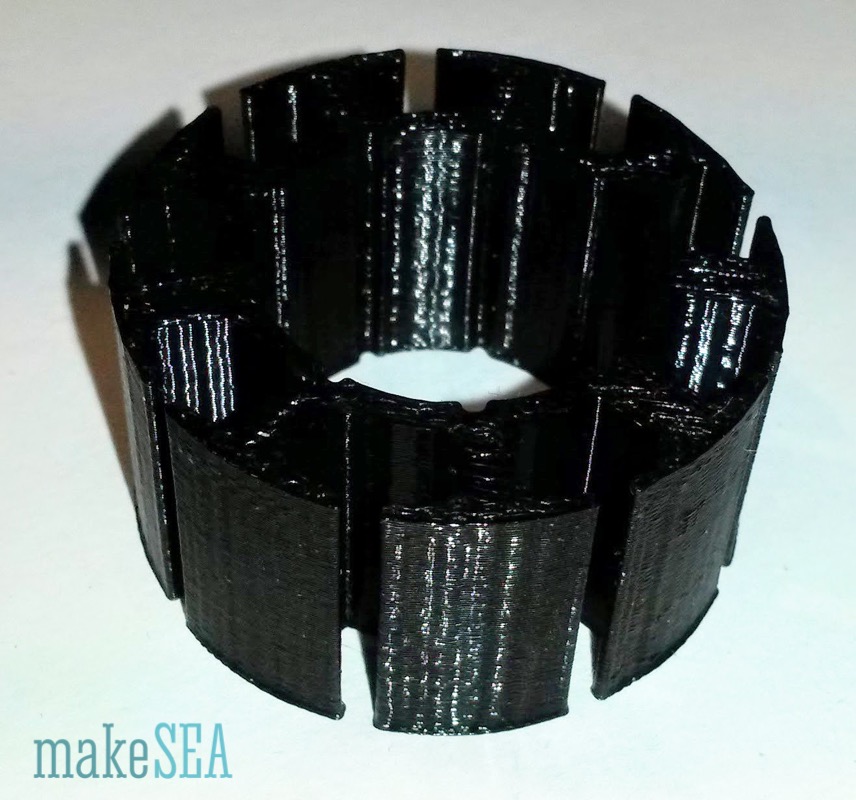

Earlier, I also tried with regular PLA, which worked at 230ÃÂðC, but not fully satisfactory. The result was a very wavy surfaceâÃÂÃÂthe temperature was by far too high, but lower temperatures also resulted in a clogged nozzle (itâÃÂÃÂs a bit difficult on the picture to recognize the mediocre printing quality with the black color).

I asked Makerbot support for help, but their response was that the Replicator 2x is only designed to print ABS and nothing else. Searching Google and YouTube wasnâÃÂÃÂt much more helpful, because there were too many unspecific results: people were printing with ABS on the R2+ and PLA on the fifth generation Replicator. Others were printing both materials with highly modded wooden pioneer Replicators, and it was not clear what makes the difference.

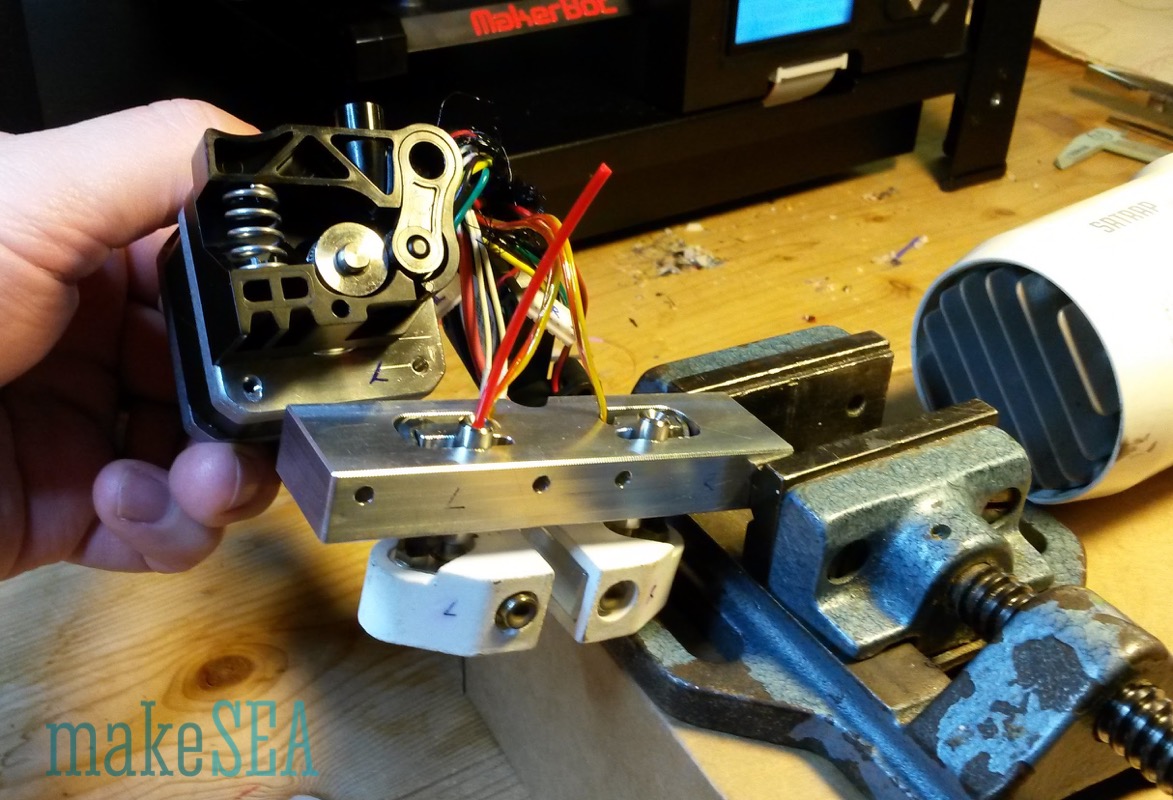

So, I started my own investigations. I started printing again with the magnetic PLA, and waited until it clogged in the nozzle. Even though the nozzle was still hot, it was very difficult to pull the filament back by hand (luckily the new print head allows you to easily release the feeder pulley). The filament looked normal. It only had a small bulge between the cold and the hot part:

I then disassembled the whole print head, fixed it in a small vice, and heated up the nozzle (using âÃÂÃÂpre-heatâÃÂàfrom the printer menu). Without feeder motors, I pushed the filament manually into the nozzle, but it never got stuck. Everything worked: normal PLA, magnetic PLA, conductive PLA, ABS, and even PETG. It wasnâÃÂÃÂt possible to reproduce the clogging. I was using the vice, because I didnâÃÂÃÂt want to burn my hands when holding the main mounting block with my fingers, but I touched it anywayâÃÂÃÂit was surprisingly cold, somewhere around body temperature. StrangeâÃÂæwhen printing, this block gets much hotterâÃÂæ

Thus, I next installed a hair dryer and heated it until the main block was feeling really hot. While still pushing the filament through the nozzle by hand, I found it needed more and more force with the increasing temperature. It seems that the friction inside the thermocoupler is increasing. So I was wondering, where does the heat come from during printing? My guess is the feeder stepper motors. The are both always turned on while printing.

When reassembling the printer, I added a sheet of paper as a thermal isolator between the motors and the main mounting block. I also placed a strong fan on top of the printer in order to sufficiently cool the motors (and the thermocoupler).

This setup had a positive effect, but still needed improvements: it was now possible to print many more layers until it clogged. Still no success, but at least I learned where the problem is located, and I was able to Google for the right terms.

I finally found several providers of different types of nozzle and thermocouplerâÃÂÃÂsome with special coated surfaces. I contacted http://www.micro-swiss.com/ and got really honest and feasable explanations. The problem is named âÃÂÃÂcold end clog." A different nozzle itself is not sufficient to resolve the problemâÃÂÃÂalso the thermal barrier tube needs to be much more efficient and with less friction. Unfortunately, there are no compatible replacement parts for the R2+.

In various forums people were also discussing lubrification of the filament. For me this seemed the last solution, because I didnâÃÂÃÂt want to contaminate the nozzles with some vaporizing oil. ItâÃÂÃÂs unclear where the oil finally goes. Encouraged by Chris Stavros I gave it a try: I designed a filament cleaner, which holds a sponge soaked with silica oil. My cleaner box can be removed and added to a filament without unloading the filament from the extruder.

STL: /documents/12185/33773/FilamentCleaningBox.stl/60dbbd65-586e-4b95-b8f0-b464f535d746

STEP: /documents/12185/33773/FilamentCleaningBox.step/9dbf5ef6-bee8-4de7-8dbe-24314f509c76

F3D: /documents/12185/33773/FilamentCleaningBox.f3d/3a5cd227-dfc4-4c30-b0a3-18f0068f0a49

In addition to lubrication, I removed the side covers of the printer and positioned the fan in order to create stronger ventilation on both extruders, the feeder motors, and the printed object.

The effect of lubrication was amazing. Magnetic PLA prints without clogging at 220ÃÂðC:

The nozzle, however, is oozing quite a lot, but at least it was possible to do a first successful print with magnetic PLA on the R2+. Finally, I reduced the temperature to 210ÃÂðC and was using Simpify3D (the software does much less travel moves over empty areas). IâÃÂÃÂm very satisfied with the final result.

Magnetic PLA used in this test purchased from:

For our Spanish speaking members, there is another video created by Associate Professor Manes Fernandez Cabanas at the Universidad de Oviedo in Spain outlining his experience with printing the Proto-Pasta magnetic PLA for use in the makeSEA brushless motor.

Pictures and video don't convert like first-hand experience does.

Research shows that using augmented (AR), and virtual reality (VR), is more compelling and more likely to persuade your audience to buy, learn, and understand what you have to share. Use makeSEA to deliver content that connects with your audience like no other medium can.

Compel your audience with

Content Management and Cross-Platform Collaboration

for Augmented and Virtual Reality

The fastest way to organize and share your content as if you are together with your audience in real life and keep it fresh using next-generation virtual and augmented reality technology.

It's time to change the way you communicate, collaborate and compel your audience.

Time to change the way you capture and curate evolving ideas.

Use makeSEA content management platform + Catapult, our cross-platform client app for mixed reality and spatial collaboration to share your vision and inspire your audience with content that you are already producing.

10X-100X Time Savings • Recyclable Content & Scenes

Use makeSEA to reduce your AR and VR production time by an order of magnitude, or two.

Blend content from multiple sources tell a better story: 3D models, real-world scans, video, and you!

Keep things fresh and relevant and improve experiences over time as your content and XR technology mature.

Enabling augmented reality, mixed reality and spatial computing for everyday use.SM

Catapult your vision, in real-time together, for FREE.

It's as easy as a social media post:

-

Create an account, start a project and upload your content from most any content source1.

-

Launch Catapult, makeSEA's mixed reality client app on your VR or AR compatible device2.

-

Share and collaborate using your own spatial content, with others together in real-time, in the same physical space and remotely.

Click Here to Get Detailed Instructions, Download and Install

Try makeSEA now! Simply register here and start publishing.

makeSEA is also available as a privately branded (white-label), or custom integrated solution for enterprise. Please Contact Us for more information.

& Design

AR/Mixed Reality

Content Publishing

& Making

& Exhibits

& Branding

1:Catapult supports assets saved in GLB (preferred), FBX, OBJ, STL or MP4 (standard 720p, 1080p, or 3K 360˚ spherical surround format), or a makeScene package for live over-the-air collaboration with shared spatial content. See the how-to guide for hints and instructions on how to easily export or convert content from most 3D authoring tools and platforms. 2:makeSEA supports Oculus Quest 2, Magic Leap 1, and Microsoft Hololens 2, makeSEA for Enterprise supports additional client devices; contact us for more information.

Trade Show Alternative

Trade Show Alternative